Tuesday 2 August 2016

Sourcing bits and pieces for my CNC router build

Saturday 30 July 2016

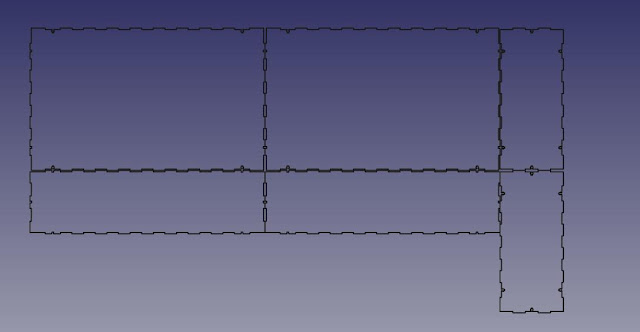

My journey in desiging a Laser cut Electronics enclosure

I was at a stage where all the required electronics components I required were in my possession and I decided to take on a new adventure of designing a laser cut acrylic enclosure.

I am quite comfortable using FreeCAD for my 3d printing design work but the software lacked the ability to make tabbed boxes. I did find a few options via FreeCAD and Inkscape but it was going to be very very hectic making things work especially with all the different formats such as .SVG, DXF, etc.

I stumbled across a website called www.makercase.com . It has a nice and simple online interface where you can with a few basic inputs quickly design a tabbed box and export an .SVG file with the design. If you want a quick tutorial on MakerCase.com you should have a quick look at this youtube tutorial: https://www.youtube.com/watch?v=ptcxaANWrRM

Below is a snap shop of the MakerCase.com website:

Tuesday 12 July 2016

Electronic Supply Source Rewiew

Monday 13 June 2016

Hobby stores are starting to emerge in Malaysia

I was casually browsing the internet looking for some diy material to build a cnc enclosure for a cnc machine that I have left half baked on the back burner and stumbled upon an interesting post on Lowyat.net posted on 1st June 2016:

https://forum.lowyat.net/topic/3963660/all

I have no affiliation with the person but it seems he has setup a new online shop by the name www.Hobby-Hardware.com

They even have a store registered at Lelong.my if you feel safer.

You can refer to the information in the lowyat link posted above for some prices he has to offer for a quick comparison.

I am more excited about the fact that they are offering a reasonable price for aluminium extruded profiles, linear hardened shafts etc, and even various 3d printing consumables such as filaments, nozzles e.t.c on their website.

They offer cutting extrusions at custom length and also shipping within Malaysia and COD at specific locations in Klang Valley.

I assume that finally people are starting to realize that there is a small hobbyist group in Malaysia that is interested in building their own 3d printers and cnc machines.

Hopefully in the near future we will have more of such shops where hobbyists can source their project raw materials.

I hope this info will be beneficial to someone who is looking for raw material to build or maintain their own custom 3d printers or cnc machines.

Friday 3 June 2016

Visit to METALTECH @ PWTC

Tuesday 22 March 2016

My Endless search for tools & machines

It has taken me alot of time and search sourcing these items and although I am dream to own beefy well made American or European machines/tools, the harsh reality is that Malaysia is not a hobby engineers or DIY heaven and most of my tools have a Asian (Taiwan/China) origin.

If you search the internet (ebay, amazon, etc) you can see lots of machines available to the western markets but sadly not many sellers will ship to Malaysia and several sellers prefer self collect/cash on delivery in the US or UK etc. For us n Malaysia we are limited to either walking from shop to shop searching for hobby grade tooling or ordering from Chinese sellers on ebay who are willing to sell and ship to anywhere n the world at a cost.

I have actually seen forums on the internet where people discriminate these China/Taiwan manufactured machines and call them as garbage, but frankly speaking its always easy to brag when you have an advantage of being in the right location. To me these cheap/hobby grade Chinese/Taiwanese machines are like gold gems.

I am not Malaysian but I do belong to a poor part of the world that spend over 30 years in war and I know that us in the eastern part of the world till a few decades ago were more worried about food, clothing and shelter. It was extremely rare for anyone in the 50'ies or 60'ies to be able to afford expensive hobbies. Today people in the eastern world can spend several thousands on photography, cycling, travelling etc.

This is probably where people in the western world are able to source some valuable gems from back in the day. They have auctions, yard sales, antique machinery shops and they are also very visible on the internet. I extremely envy all those lucky people.

Sometimes the stuff I look for is no longer in production and have been made obsolete simply because of new and expensive technology available to replace them. And quite frankly I have been very very un-successful in finding any of the items on my treasure hunt list. Even people in the trade in this part of the world have never seen such machines nor have they ever used them. I guess in the eastern world people just make do of what they have available or outsource it commercially.

Let me share with you today just 3 items from my treasure hunt list. Several normal people have never even seen these items in real life nor would they be able to guess what they even do or are used for. Here we go:

1. Finger Plate: It is primarily used to hold small delicate objects that need to be drilled or machined. That simple right but imagine drilling a hole or milling through a piece of metal that barely measures a few centimeters. Most hobby machinists make there own now as its not in production anymore.

2. Die Filer or Parallel Filing Machine: A die filer is one of those tools that you see pop up from time to time in magazines or construction manuals. The owners of these machines always speak very highly of them, yet commercial manufacture of these tools ceased a long time ago. You can not even find the parallel files that are used on these machines any more. I had been looking for one on Ebay for years but have not been lucky. They help file edges, make square holes, etc. Imagine all the time you can save with this machine vs filing by hand. There are several casting kits available online that can be shop finished to make one for yourself but the cost of even shipping the castings kit to Malaysia will cost you a ton.

|

| A photo of the kind of parallel machine files used with a die filer. They are no longer commercially available. |

3. Metal Shaper: A metal shaper generally uses single point tools, like those use in a lathe to cut metal in a series of straight lines. A shaper cuts much flatter surfaces than a mill with a face mill cutter. No matter how square the facemill is, it will deflect a bit under load and cut a very shallow scallop. First time you hand scrape a shaped surface versus a milled surface, you will understand how "unflat" the milled surface really is. Unfortunately for several people in the trade they general statement is: "you can make anything but money with a shaper". A shaper is also VERY slow, when compared to a mill of similar power and capacity. A shaper spends about 45% of the time doing nothing as the ram retracts for another cutting stroke. But to me, the flatness you can achieve with a metal shaper is exceptionally perfect. I have seen a few very large industrial grade metal shaper's in machine shops in person but they are too large for hobby purposes where we usually would prefer a 5" or a 7" benchtop model.

Although time has moved on and these machines have been forgotten, for the hobby machinists, these are still a gem and are very useful in our home base garages or home machine shops.

Sad to say, I may never get my hands on any of these in the near future within my current capabilities financial (else I could have paid a ton in price & shipping to order these second hand from US or UK) but my quest continues and hopefully I will come across one in Asia.

A never ending quest and my list will probably keep on growing larger. Sour grapes!!

Sunday 6 March 2016

A Gypsy's Home Workshop/Store (Moving Soon)

|

| A view of the small store room converted to my DIY shop |

|

| The mill, lathe and 3d printer with dust covers placed on a TV display unit the house had available |

|

| The mill, lathe and 3d printer with dust covers removed |

|

| My Sieg SX2P Mini Mill Machine |

|

| Accessories & Tooling for the Sieg SX2P Mill stored in the drawer below. |

|

| My Sieg SC2 Mini Lathe |

|

| Accessories & Tooling for the Sieg SC2 Lathe stored in the drawer below |

|

| One of the drawers holding various measurement and layout tools |

|

| My DIY Prusa i3 Reprap Printer |

|

| A drawer below the 3d printer where I stored the Granite Surface Plate and some instruction manuals |

|

| A white board to make quick notes or instructions |

|

| An over head cupboard showing a LED Mill/Lathe work light and drill machine drill press stand |

|

| Various electronics & stationary items stored in the overhead cupboard |

|

| A domestic grade vacuum cleaner to keep the DY shop clean from swarf, chips and debris |

|

| My Waytrain UE-100S Bandsaw which is 4x6 inch model. I do not even have a proper place to mount it and only take it out when I need to do some quick metal cuts. |

|

| In this corner, we have some typical motorcycle stands, a fan, dehumidifier, a work bench, shop stool etc |

|

| Fresh aluminium, brass and delrin blanks and some salvaged material from previous projects |

|

| Salvaged electrical items stored in a mini cupboard |

|

| A spare cupboard the house had that used to store various things |

|

| A section where have an incomplete DIY CNC machine (a project that will be going to the back burner for now) and a belt sander |

|

| A section of the cupboard storing various lubricants, greases, oils and motorcycle spare parts |

|

|

|

| A section for storing various hand tools |

|

| A section for storing various hand tools and abrasives etc |

|

| A section for power tools and some other miscellaneous items |

|

| A section storing various tools and lubricants for rough use |

Cheers!!