On my CNC 3020 router which I put together as a bag of random bits bought off AliExpress, I had decided to go with a Generic 1.5kW Air-cooled cnc spindle. I had contacted the manufacturer for the torque-power curve chart related to the spindle but I received no plausible response. Even the spindle specifications mentioned on most AliExpress and Ebay listings seemed to be a bit vague and over estimated. Some listings for 1.5kW spindles had torque-power curve profiles copied from 2.2kW spindle listings. So, basically there was always some uncertainty in the information.

Several people have been using such spindles on their routers with great success after tweaking the parameters based on practical experience and best guesses, but I wanted something that was mathematically sensible. After putting several hours building the machine, the last time I wanted was something catastrophic happening. So I decided to do my research first before diving in to the deep end with no previous CNC experience.

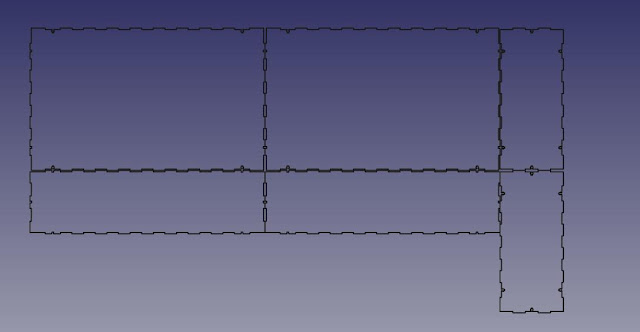

I was playing with a demo version of the HSMAdvisor to determine some usable feeds and speeds for cutting T6061 aluminium and there were several machine profiles available for download from the cloud. One specific profile related to Generic Chinese CNC spindles is also provided but the profile seems too generic as below:

The above machine profile in HSMAdvisor seems to have been created in HSMAdvisor using the Power Curve Wizard and is a bit far from theoretical expectations of such high rpm spindles.

In an effort to create a real life usable machine profile, I started researching into the torque power curves for similar 1.5kW cnc spindles and it seemed most European manufactures were fairly transparent with regards to the specifications and torque power curves of the spindles they were selling.

Below is one such example of a 1.5kW spindle motor from a German manufacturer with similar power, rpm ranges and over all design:

I also found a power curve for another 1.1kW spindle motor from another German manufacturer as below:

Next, I wanted to calculate the best match torque-power curve for my generic Chinese CNC spindle using the specifications from information I gathered from various European manufacturers. To do this I had to understand the science behind torque & power curves and their relationship to motor specifications.

The German manufacturer that I borrowed the previous power curve charts also provided FAQ's related to the science behind how the power and torque of a motor are related to RPM etc as follows:

Now, I had enough information and proceeded to Excel to do my calculations:

Now, I was ready to create a best fit profile for my generic cnc spindle in HSMAdvisor:

At first, the resulting graph did not look very clean or refined as there curves appeared irregular, but then there must be something not perfect with the way graphs are plotted in HSMAdvisor.

I also reduced my Max Feed as my router cannot exceed 800mm/min before stalling while traversing an axis (something I realized via the Motor tuning wizard in Mach3).Stepper motors have their own torque curves which clearly indicate alot of torque in the low rpm ranges and I do not expect to chew through metal on a small router as a industrial grade cnc milling machine.

With the power curve setup in HSMAdvisor, I proceeded to calculate feeds and speeds for milling and drilling Al T6061 and machineable wax. The result was amazing, I made my first test parts on a tiny 3020 router with a 1.5kW spindle without any hiccups- no motor stalls, no broken milling bits, no jams.